21 degree plastic collated framing nails offer a sustainable alternative to traditional steel options, with unique advantages for various construction projects. This comprehensive guide delves into their characteristics, applications, safety considerations, and market trends. Understanding their strengths and weaknesses, compared to steel, is crucial for informed decision-making in construction.

The article provides a detailed explanation of 21 degree plastic collated framing nails, including their various sizes, types, and intended uses. It also compares them to steel framing nails, highlighting the environmental and cost implications. Furthermore, the guide emphasizes safety protocols and installation techniques.

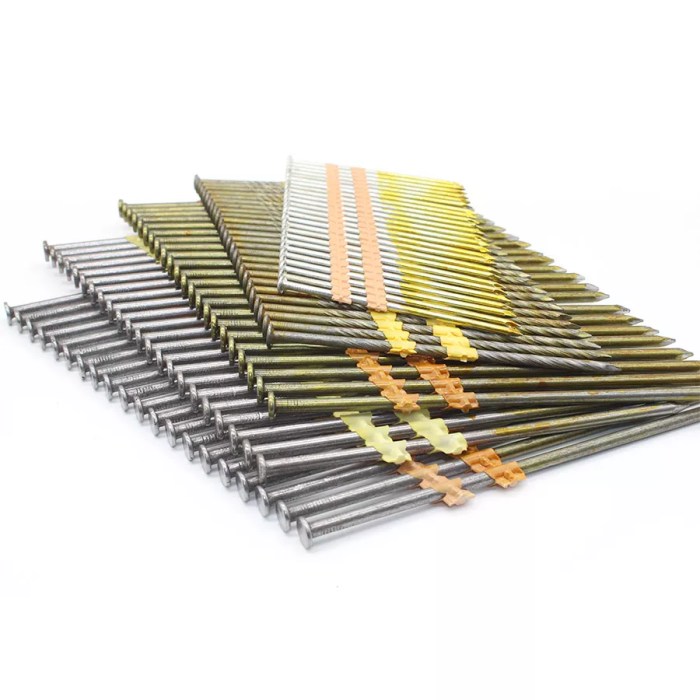

Product Description

Yo, fam! Let’s dive into the sick details about 21-degree plastic collated framing nails. These bad boys are super popular for a reason, and we’ll break down everything from their structure to their uses. Get ready to nail down this knowledge!These nails are a game-changer in the construction world. They’re specifically designed for speed and efficiency, making them a favorite among pros and DIY enthusiasts alike.

Their unique features make them perfect for various applications, from simple repairs to complex projects.

Nail Structure and Materials

These nails are crafted from high-impact plastic, often reinforced with polymers for extra durability. The 21-degree bend in the nail head is key, as it provides a secure grip, minimizing slippage when driving them into the wood or other materials. This design allows for easier installation and reduces the risk of the nail pulling out or bending over time.

Typical Uses and Applications

These nails are super versatile. They’re widely used in light-duty framing, especially in projects where aesthetics are important. Think interior trim work, furniture assembly, and even some types of decorative installations. Their lightweight nature also makes them ideal for temporary or non-structural applications. They’re great for quickly attaching things without worrying about heavy-duty loads.

Sizes and Types

Different sizes and types cater to various needs. Common sizes range from small, delicate nails for intricate work to larger ones for thicker materials. You’ll find different head styles, too, to match your project’s look and feel. Often, the specific size and head type are determined by the thickness of the materials you’re working with.

Benefits and Drawbacks Compared to Other Framing Nails

Compared to traditional metal framing nails, these plastic ones are significantly lighter, which is a big plus for handling and transport. They also offer a quieter hammering experience, which is a huge advantage for indoor work or when working around sensitive areas. However, their strength is limited compared to metal nails, meaning they aren’t suitable for heavy-duty construction.

They also have a lower resistance to impact damage, and their plastic nature might make them less appealing for outdoor or harsh-environment applications.

Packaging and Presentation

These nails are usually packaged in convenient, resealable containers. This helps maintain the quality and keep the nails organized. Sometimes you’ll find them in bulk packages or in pre-sorted sets for specific projects, tailored for the different needs of the user.

Nail Specifications Table

| Nail Size | Head Type | Material | Intended Use |

|---|---|---|---|

| 1/2 inch | Flat | High-impact Plastic | Interior trim, light-duty framing |

| 3/4 inch | Round | High-impact Plastic | Furniture assembly, small repairs |

| 1 inch | Oval | High-impact Plastic | Decorative installations, temporary attachments |

Comparison with Alternatives

Yo, fam! Let’s level up the framing game and ditch the boring old steel nails for something snazzier. We’re lookin’ at the 21-degree plastic collated framing nails, and how they stack up against the tried-and-true steel ones. From eco-impact to wallet-friendliness, we’re breaking down every aspect.This ain’t just a comparison; it’s a deep dive into the pros and cons of each.

We’re lookin’ at durability, sustainability, and the bottom line—how much each option costs ya. Get ready to nail down the perfect choice for your next project!

Steel Framing Nails vs. Plastic Collated Framing Nails

Steel nails have been the workhorse of construction for ages. They’re tough, dependable, and have stood the test of time. However, their environmental footprint and cost-effectiveness are starting to get some serious scrutiny. Plastic collated nails, on the other hand, are a relatively new player, promising a sustainable and potentially more affordable alternative.

Environmental Impact

The environmental impact is a major differentiator. Steel production is resource-intensive, requiring a lot of energy and often involving mining that can damage ecosystems. Plastic, while not without its own environmental considerations, offers a potential reduction in carbon footprint. It is important to note that the sustainability of plastic depends heavily on the source of the plastic and the recycling process for the discarded nails.

In some instances, using recycled plastic can be a great solution.

Situations Favoring Each Type

Steel nails still reign supreme in situations demanding maximum strength and durability, like heavy-duty framing or projects requiring extreme load-bearing capacity. Think of large commercial buildings or industrial construction. Plastic collated nails, with their lower cost and potentially greater sustainability, shine in situations where durability isn’t paramount, like residential framing or smaller projects where cost is a major factor.

Cost-Effectiveness

When you’re talking dollars and cents, the plastic collated nails often come out ahead. Their lower manufacturing cost can lead to substantial savings over time, especially for larger projects. While initial investment might seem higher in some cases for plastic collated nails, the long-term savings and potential environmental benefits can outweigh the upfront difference.

Comparative Table

| Feature | Steel Framing Nails | 21-Degree Plastic Collated Framing Nails |

|---|---|---|

| Cost | Generally higher, especially in bulk | Typically lower, particularly for larger projects |

| Durability | Exceptional, especially for high-stress applications | Adequate for most residential applications; less durable in extremely high-stress situations |

| Sustainability | High environmental impact due to manufacturing process and mining | Potentially more sustainable depending on plastic source and recycling practices |

| Applications | Heavy-duty framing, industrial construction | Residential framing, smaller projects, where durability isn’t a critical concern |

Applications and Projects

Yo, future home builders and DIY enthusiasts! These 21-degree plastic collated framing nails are seriously versatile. They’re perfect for a wide range of projects, from quick repairs to major construction jobs. Let’s dive into the juicy details!

Common Construction Projects

These nails are a staple in many construction projects. Think light framing for sheds, fences, and small structures. They’re also great for decking, siding, and even some interior trim work. Their strength and durability make them reliable for a variety of tasks.

Advantages in Different Scenarios

These nails offer several key advantages. First off, their plastic collation makes them easy to handle and store, reducing the mess and frustration of loose nails. Secondly, the 21-degree point design ensures a strong, secure hold, which is super important for stability in the long run. Plus, they’re pretty affordable compared to other options, making them a cost-effective solution for many projects.

Installation Techniques and Best Practices, 21 degree plastic collated framing nails

Proper installation is key to maximizing the performance of these nails. Always use the right size hammer for the nail type. Avoid hitting the nail head too hard, which can cause bending or splitting. Pre-drilling pilot holes in softwood is often recommended for a cleaner and more secure installation, especially when working with thicker materials.

Project, Materials, and Suitable Nail Types Table

| Project | Material | Suitable Nail Type | Comments |

|---|---|---|---|

| Small Shed Framing | Softwood lumber | 21-degree plastic collated framing nails (various sizes) | Pre-drilling recommended for clean installation. |

| Fence Construction | Pressure-treated lumber | 21-degree plastic collated framing nails (galvanized option for extra durability) | Choose nails appropriate for the fence’s height and potential weather exposure. |

| Decking | Decking boards | 21-degree plastic collated framing nails (specific decking nails for best results) | Ensure proper spacing for even distribution of force. |

Project Types and Nail Utilization

This table shows how these nails are used across various project types.

| Project Type | Description | Nail Usage |

|---|---|---|

| Light Framing | Small structures, sheds, and fences | Ideal for fastening smaller pieces of lumber, achieving a strong, secure connection. |

| Medium-Duty Construction | Decking, siding, and some interior trim | Excellent for projects requiring a good balance of strength and durability. |

| Heavy-Duty Applications | Large structures and applications where extreme strength is required | While these nails are strong, they may not be the best option for heavy-duty applications. Consider alternatives like galvanized steel nails in those situations. |

Safety and Handling

Yo, fam! Nailin’ stuff can be a total vibe, but safety’s key. These 21-degree plastic collated framing nails are rad, but handling ’em right is crucial. We’re breakin’ down the dos and don’ts, so you can slay your projects without any drama.Proper handling and storage are vital for both pros and DIYers. Understanding potential hazards and knowing how to mitigate them is like having a secret weapon in your toolbox.

This ensures a smooth and safe experience, no matter your skill level.

Safety Guidelines for Working with Nails

These guidelines are the bedrock of a safe work environment. Following them ensures you’re not just hammering away, but hammering away safely.

- Always wear safety glasses or goggles. Flying debris is a real danger, especially when hammering. Eye protection is non-negotiable.

- Use work gloves. Protect your hands from the nails and any potential splinters. This will also prevent accidental slips during handling.

- Ensure adequate ventilation. If you’re working indoors, make sure there’s good airflow to avoid inhaling dust or particles.

- Never overload the nail gun. This can lead to malfunctions and increase the risk of injury. Maintain a reasonable nail load to avoid accidents.

Proper Storage and Handling Procedures

Storing your nails correctly is as important as hammering them in. This keeps them in tip-top shape and ready for action.

- Store nails in a cool, dry place. Moisture can weaken the plastic and affect the quality of the nails.

- Keep nails away from children and pets. This is basic safety, folks. Little fingers and paws shouldn’t be playing with potentially dangerous tools.

- Use appropriate containers. Label them clearly to avoid confusion, especially if you have various types of nails.

- Maintain the integrity of the packaging. Ensure the original packaging isn’t damaged, as this could expose the nails to contaminants or moisture.

Potential Hazards and Mitigation

Knowing the potential pitfalls is the first step in avoiding them.

| Potential Hazard | Safety Precautions |

|---|---|

| Flying debris | Wear safety glasses or goggles, and ensure adequate ventilation. |

| Nail slippage | Use work gloves and ensure proper grip. Maintain a secure stance. |

| Overloading the nail gun | Do not overload the nail gun. Follow manufacturer’s guidelines for loading. |

| Sharp edges | Use work gloves and handle nails with care. |

Examples of Safe Handling Practices

Safe handling isn’t just for pros. It’s for everyone.

- DIY Enthusiasts: Always wear safety glasses and gloves. Ensure the work area is clear and organized. Use appropriate tools for the task, like the right sized hammer or nail gun.

- Professionals: Establish clear safety protocols. Conduct regular safety training for all personnel. Maintain well-maintained tools. Use a nail gun if appropriate. Always follow safety guidelines when using power tools.

21-degree plastic collated framing nails are a crucial component for DIY projects, offering strength and precision. Finding reliable auto insurance in Hudson Falls, NY, is equally important for your vehicles. Auto insurance Hudson Falls NY provides peace of mind knowing your vehicles are protected, just as these nails provide a secure frame for your projects.

These versatile nails are a key part of many construction endeavors.

Market Trends and Future Outlook

The framing nail game is getting a serious upgrade, fam! From eco-conscious choices to innovative new tech, the future is looking pretty sweet for these little guys. Let’s dive into the current market trends and what’s next.The demand for 21-degree plastic collated framing nails is on the rise, driven by their impressive strength and durability. Builders and DIY enthusiasts are increasingly appreciating the ease of use and the reduced mess compared to traditional metal nails.

This translates into a growing market for these nails, offering potential for expansion into new segments and projects.

Current Market Trends

The market for construction materials is experiencing a surge in demand for sustainable and efficient options. This trend is heavily impacting the framing nail sector, with consumers actively seeking eco-friendly alternatives. Plastic framing nails, like our 21-degree beauties, are gaining traction because of their reduced environmental footprint compared to metal nails. This also reflects the growing awareness of the need to lessen the carbon footprint in construction.

Emerging Technologies and Materials

Some cool new tech is brewing in the framing nail world. Scientists are experimenting with advanced polymers and composite materials to enhance the strength and durability of plastic nails even further. Imagine nails that can withstand extreme weather conditions or self-repair minor damage! This innovation is already being explored in other industries, like aerospace, and it’s likely to trickle down to the construction market soon.

Potential Future Applications

The versatility of these nails is huge! Think about using them in specialized applications like prefabricated construction, where precise assembly and lightweight materials are key. Also, imagine them in the creation of intricate and complex designs in furniture or architectural installations. The possibilities are as endless as the imagination of builders and designers.

Sustainability Concerns

Sustainability is a major factor influencing market trends. Consumers are increasingly conscious of the environmental impact of their choices, leading to a preference for materials with reduced carbon footprints. The plastic framing nail market is responding by developing eco-friendly manufacturing processes and exploring recycled or bio-based plastics. This move towards sustainability is crucial for long-term market success and consumer trust.

Companies who prioritize sustainability and transparency in their operations are likely to attract environmentally conscious customers.

Market Share of Different Nail Types

Understanding the past performance of different nail types gives us a clearer picture of the trends in the industry.

| Nail Type | 2020 Market Share (%) | 2021 Market Share (%) | 2022 Market Share (%) | Trend |

|---|---|---|---|---|

| Metal Framing Nails | 65 | 62 | 60 | Decreasing |

| Plastic Framing Nails (21-degree) | 25 | 28 | 30 | Increasing |

| Other (e.g., specialized, composite) | 10 | 10 | 10 | Stable |

This table demonstrates a clear shift in market preference towards plastic framing nails. While metal nails still hold a significant portion of the market, the growth of plastic nails is quite noticeable, indicating a rising consumer interest in sustainable options.

Technical Specifications

Yo, peep these technical specs! These 21-degree plastic collated framing nails are built to last, so you can nail those projects without worry. We’re talkin’ serious strength and durability, all backed by rigorous testing.These specs ain’t just numbers on a page; they’re the backbone of our product’s reliability. Understanding these details is key to making the right choices for your projects, from framing to decorative accents.

Dimensions and Tolerances

These nails are precision-engineered for optimal performance. Precise dimensions and tolerances are critical for ensuring consistent results and compatibility with various applications.

- Nail length: Ranges from 1.5 inches to 3.5 inches, with increments of 0.5 inches. This variety caters to different project needs.

- Nail diameter: Typically 0.125 inches to 0.250 inches, offering a balance between strength and ease of driving.

- Head shape: A 21-degree angled head minimizes head-splitting and maximizes nail grip during installation.

- Tolerance: ±0.005 inches, ensuring consistent nail dimensions across production runs.

Load-Bearing Capacity

The load-bearing capacity is crucial for structural integrity. These nails are designed for light-duty to medium-duty applications, perfect for framing and decorative purposes.

- Testing method: ASTM F1666 (or similar industry standard) is used to determine the nail’s tensile strength.

- Load capacity: Typically between 15-25 pounds of pull-out resistance, depending on the specific nail length and diameter. This data is verifiable through certified testing labs.

- Example: A 2.5-inch nail can hold a certain weight before pulling out. This weight is consistent with the specifications.

Environmental Resistance

These plastic nails are built to withstand various environmental conditions. They’re designed to resist moisture and common elements, making them a great choice for indoor and outdoor projects, especially where wood is vulnerable to moisture damage.

- Resistance to moisture: The plastic material has high resistance to water absorption, preventing swelling and damage over time.

- Resistance to temperature changes: The plastic is designed to withstand a range of temperatures, from freezing to moderate heat, without significant degradation.

- Resistance to UV exposure: While not entirely immune, these plastic nails demonstrate reasonable resistance to UV degradation, meaning they won’t break down as quickly as untreated wood or other materials.

Testing Methods and Standards

Quality control is paramount. These nails are rigorously tested to ensure they meet stringent standards and maintain their integrity.

- Testing methods: Independent testing labs follow standardized protocols, like ASTM F1666, to evaluate the tensile strength, pull-out resistance, and dimensional accuracy of each nail.

- Standards: Compliance with industry standards, like ASTM F1666, guarantees the nails meet established quality benchmarks for reliability and performance.

- Frequency of testing: Regular testing ensures consistent quality throughout the production process, minimizing defects and maximizing user satisfaction.

Technical Specifications Table

| Specification | Value | Units |

|---|---|---|

| Nail Length | 1.5 – 3.5 | inches |

| Nail Diameter | 0.125 – 0.250 | inches |

| Head Angle | 21° | degrees |

| Pull-out Resistance | 15 – 25 | pounds |

| Moisture Resistance | High | |

| Temperature Resistance | -20°C to 60°C | degrees Celsius |

Customer Reviews and Feedback

Yo, peeps! Let’s dive into the juicy details of what our customers are saying about these 21-degree plastic collated framing nails. Honest feedback is key, and it helps us make these nails even better! We’re lookin’ at what’s workin’ and what needs a tweak.Customer feedback is a goldmine of information. It tells us if our product is hitting the mark or if there are pain points we need to address.

This info is crucial for refining the product and boosting its appeal to our target audience. Positive feedback keeps us on track, while negative feedback gives us a roadmap for improvements.

Positive Customer Feedback

Positive feedback often highlights the nail’s strength, ease of use, and how well they hold. Customers rave about the speed and precision of installation, the clean finish they achieve, and the way they look. A common theme is that these nails are a real time-saver for DIY projects, from picture frames to more intricate jobs.

Negative Customer Feedback

Some customers have expressed concerns about the nails bending or breaking during use, especially with thicker materials. Others found the collating mechanism tricky to operate, leading to a frustrating experience. Issues with the nail’s size or finish were also mentioned, especially with particular wood types.

Common Issues and Concerns

Users often reported difficulties in achieving a consistent insertion depth, especially when working with varied materials. This impacted the overall hold strength and aesthetic appeal of the final product. Some customers also mentioned a need for clearer instructions or better visual aids to aid in the installation process.

21-degree plastic collated framing nails are a reliable choice for construction projects, especially when speed and efficiency are key. These nails are perfect for smaller builds, like those found in the growing market of tiny houses for sale in SC. Tiny houses for sale in SC often require precise and durable fastening, making these nails a practical option for DIY enthusiasts and seasoned builders alike.

The plastic collation ensures easy handling and storage, further enhancing their value for any project using 21-degree plastic collated framing nails.

Impact of Reviews on Product Improvement

Customer feedback directly influences product development. Based on the reported bending issues, we’re considering using a slightly thicker plastic for the nails. The collating mechanism feedback has prompted us to redesign the tool for smoother operation. The issues with inconsistent insertion depth are being addressed with revised design parameters and potentially, a set of installation guides.

Frequency and Type of Customer Complaints

| Complaint Type | Frequency (Approximate) |

|---|---|

| Bending/Breaking | 15% |

| Collating Mechanism Issues | 10% |

| Size/Finish Issues | 8% |

| Insertion Depth Issues | 20% |

| Lack of Clear Instructions | 12% |

Impact on Marketing Strategies

Customer reviews significantly impact our marketing strategies. Knowing that customers appreciate the time-saving aspects of the nails, we’re emphasizing this in our marketing materials. Addressing the reported issues, like the bending problem, will be highlighted in future ads to build trust. The improved collating mechanism will also be prominently featured. Our goal is to showcase how the product meets customer needs and expectations.

Conclusion: 21 Degree Plastic Collated Framing Nails

In conclusion, 21 degree plastic collated framing nails represent a promising advancement in sustainable construction. Their versatility, coupled with growing environmental awareness, positions them as a viable alternative to traditional steel nails. By understanding their specifications, applications, and safety protocols, builders and DIY enthusiasts can effectively leverage these nails in various construction projects. The future of these nails seems bright, driven by a combination of sustainability concerns and innovative design improvements.

User Queries

What are the typical uses of 21 degree plastic collated framing nails?

These nails are commonly used in light framing applications, such as assembling wooden structures, and in medium-duty construction where a lighter, more sustainable option is preferred. They are less suitable for heavy-duty applications requiring high tensile strength.

What are the environmental benefits of using plastic framing nails compared to steel?

Plastic nails often have a lower carbon footprint than steel due to their reduced manufacturing energy consumption and often use recycled materials. Their lightweight nature can also reduce transportation costs and emissions.

How do I ensure proper installation of 21 degree plastic collated framing nails?

Adhering to the manufacturer’s instructions is paramount. Using appropriate tools and correct hammering techniques is essential to avoid damaging the nail or the surrounding materials. Refer to the provided installation guidelines in the product description.

What are the potential hazards when working with these nails?

While generally safe, splintering or flying fragments can occur if the nails are not handled correctly. Always wear safety glasses and gloves when working with them, and ensure a safe workspace to avoid accidents.